Summary

– Step 1: Turn off the water

– Step 2: Locate and cut out the damaged part of the PVC pipe.

– Step 3: Deburr the remaining sections

– Step 4: Degrease contact surfaces

– Step 5: Deglaze the contact surfaces

– Step 6: Measure the section of pipe to be replaced

– Step 7: Cut the new section of PVC pipe

– Step 8: Prepare the assembly of the new section

– Step 9: Glue the contact surfaces

– Step 10: Assemble sleeves and tube

– Step 11: Check for leaks

If properly bonded, a PVC tube will not leak. But it can be damaged by a strong shock or burst due to frost. The damaged section or element must then be replaced: connector, siphon, etc.

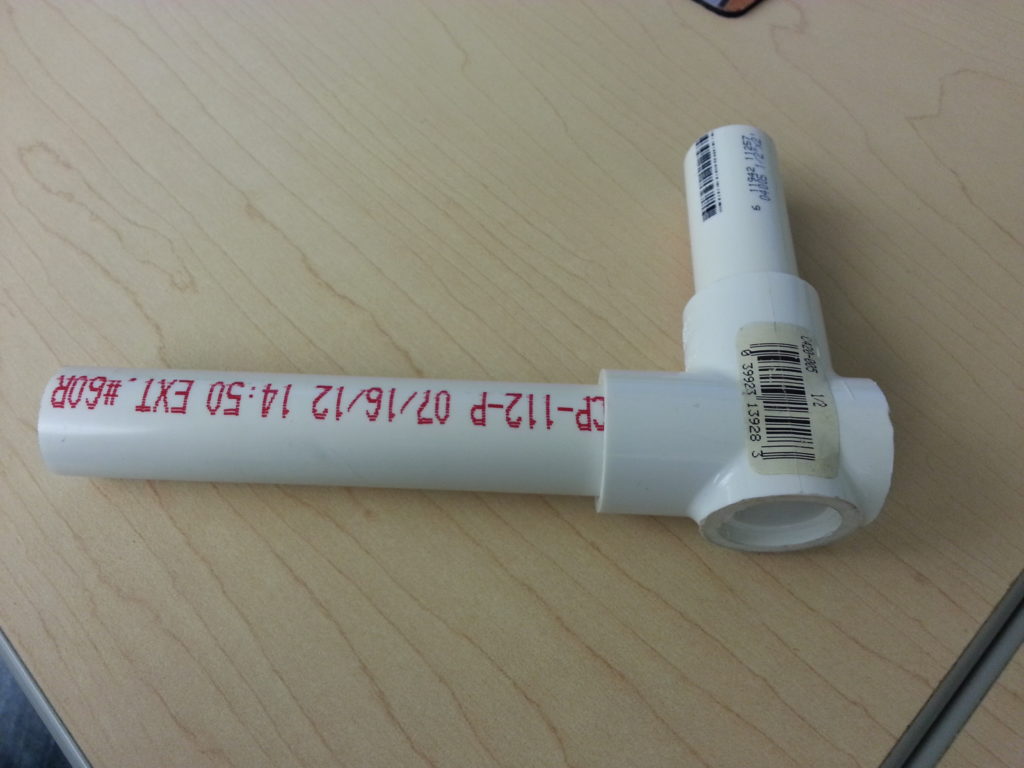

This replacement is simple: it uses a new tube of the same diameter and cut to the damaged section’s length. The new one will be assembled using female-female couplings (sleeves), also made of PVC: threaded at its ends and the remaining parts of the pipe.

Note: the diameters of PVC pipes are standardized and always measured outside (32, 40, 50 mm…). This is also the case for male fittings. The diameters of the female fittings are inside.

Here is the step-by-step method to repair a leak in a PVC pipe.

1. Turn off the water

Since PVC is used for drains, make sure that no one will run water at the faucets located upstream from the damaged area. If in doubt, turn off the water in the corresponding circuits while the repair is carried out.

2. Locate and cut out the damaged part of the PVC pipe

Trace the cut-out to be made on both sides of the damaged part: you can stick 2 lengths of adhesive tape straight around the pipe at the desired places.

To cut out the damaged part, depending on the free space on either side of the pipe and the equipment you have, you can use :

– a hacksaw ;

– a handsaw ;

– a reciprocating saw;

– or a multi-function tool equipped with a fine-toothed semi-circular blade.

3. Deburr the remaining sections

Unless a special PVC pipe cutter is used, all toothed blades produce chips and burrs that partially adhere to the cut pieces. The ideal is to use a deburrer for deburring the remaining sections, but it may not fit between the pipe and the wall.

In this case, use :

– a small knife;

– a cutter;

– or a piece of abrasive paper (coarse grit: 100 or less) folded on itself.

4. Degrease the contact surfaces

Degrease the inside of the sleeves with a sheet of paper towel impregnated with methylated spirits.

Do the same for 3 to 5 cm at the pipe’s remaining ends if they look dirty.

If there is only dust, clean them with a little household detergent on a damp sponge, rinse and dry.

5. Degrease the contact surfaces

Deglazing the surface of the PVC allows the glue to adhere better.

Tip: Rub inside the ends of the pipe for 3 to 5 cm with sandpaper.

6. Measure the length of pipe to be replaced.

Measure the part to be replaced and deduct 1 cm from the length obtained.

7. Cut the new section of PVC pipe

Place the new tube in the jaws of a folding workbench or vice, without tightening too much.

Locate the length to be cut.

Cut the tube as straight as possible and deburr the end.

Then check that it corresponds to the damaged part minus 1 cm.

8. Prepare the assembly of the new section

You will not install the new section without slightly moving one of the remaining pipe sections.

Open the clamps holding the shortest section to move it away from the wall or remove it altogether (if it ends in a trap, for example).

9. Glue the contact surfaces

Apply the glue (for rigid PVC) on the deglazed surfaces:

either the inside of the sleeves ;

or at the ends of the original pipe and pipe sections.

Note: You do not need to apply a lot of glue but spread it evenly with your fingertip.

10. Assemble the sleeves and tube

Thread (without turning) the sleeves at the ends of the new tube.

Alternatively, thread one sleeve onto the end of one pipe section and then incorporate the other sleeve onto the other pipe section’s end.

Finally, thread the tube on one side and then on the other.

11. Check for leaks

After waiting the indicated time (1 or 2 hours) :

Re-open the shut-off valve(s) and inspect the repair.

If the bonding has been well done, there should be no oozing.