Interest and Usefulness of the Different Plumbing Shut-off Valves

Contents

– Interest and usefulness of the different shut-off valves

– Buying a shut-off valve

– Maintenance and repair of shut-off valves

A valve is a device with a moving part that can be operated to regulate the flow of a fluid through a pipe. The valve is, therefore, a flow control device. The shut-off valve, on the other hand, makes it possible to open and, above all, to close a pipe completely. Let’s see closer below.

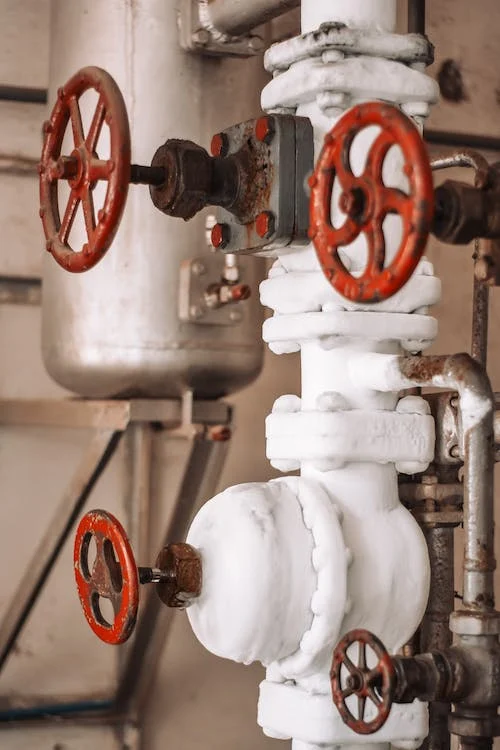

Interest and usefulness of the different shut-off valves

If the tap is the equivalent of a valve, the term tap is reserved for small devices, while the valves are larger and placed on pipes with a larger diameter.

Whether it is a valve or a shut-off valve, the name is only really important on the diagrams, especially on those of specific networks (fire, industry, boiler room, etc.).

In fact, any valve capable of modulating a fluid flow is also capable of stopping it in a totally tight manner.

There are several types of valves, qualified according to their design.

Good to know: if the name “fluid” is often preferred to that of liquid, it is because of the use of valves on networks of more solid materials, such as sludge, or less dense, such as steam or gas.

Plug valve

In this type of valve, a device pivots to open or block the passage of fluid partially or completely.

Among these valves, generally quarter-turn (because of the 90° stroke of the handle) or half-turn, there are several sub-categories:

In the case of the ball valve, it is a hollow ball that is actuated. When the valve is open, the fluid flows through the recess, whereas when it is closed, the fluid hits the wall of the ball. This valve is much more suitable for use as a shut-off valve than for regulating the flow of a pressurized fluid.

The butterfly valve is so called because it is a butterfly (flap) that rotates 90° on its axis to open, close, or regulate the flow of fluid.

Spool Valve

Also known as a gate valve, this valve is equipped with a handwheel that lowers a flap within the pipe, similar to a guillotine.

In the raised position, the flap (or gate) is raised in the valve’s body and leaves the passage completely free of the fluid (direct passage). The possible flow diameter is gradually reduced by lowering the flap through the handwheel.

The slide valve is suitable for both control and shut-off functions, especially for water and air.

Globe valve (or flap valve)

This type of valve has a seat into which a conical plug (valve) descends to a greater or lesser extent to regulate, circulate or stop the flow.

The descent of the plug (valve) is generally made progressively by a screw wheel.

Diaphragm valve

It replaces the seat and the valve of the globe valve with a deformable membrane, which is gradually pushed into the pipe to reduce the diameter of the fluid passage.

The diaphragm valve is not very suitable as a shut-off valve for thick media but is much more useful for flow control or in air or gas systems.

Good to know: because of the sealing constraints due to the different densities of the fluids, ball valves, and diaphragm valves are preferred for steam systems, whether for shut-off and regulation (diaphragm valve) or shut-off (ball valve).

Regardless of the type of shut-off valve and its operating system (lever, handle, or screw wheel), the vast majority of shut-off valves can be controlled or piloted remotely by an operator or an automatic system.

The motorization of valves can be electric, automatic, spring-loaded, triggered, pneumatic or other, depending on the environment in which it is used (explosive or dangerous atmosphere, etc.).

Buying a shut-off valve

The price of a shut-off valve varies greatly. It depends on various factors.

Amount of material

A valve of a small section (domestic) requires much less technique, and especially much less material, than a valve of big diameter used on a collective supply network or in an industry.

The price of the valves, therefore, depends primarily on the diameter of the pipe they are to equip.

The technicality of the material and assemblies

The food, neutral or corrosive nature of the fluid that is to flow through the shut-off valve requires the use of specific materials, both for the valve body and for the shut-off element(s).

A domestic shut-off valve made of plastic or nylon is generally less expensive than a valve of the same diameter made of brass or stainless steel.

Pressure and temperature ratings

The body, but also the mechanism of the valve, must be able to contain a low pressure (swimming pool, gas, domestic water, etc.), always lower than 20 bars, with a moderate temperature.

Industrial or fire safety shut-off valves, on the other hand, must be able to withstand much higher pressures and sometimes at very low or very high temperatures (steam, smoke, etc.).

Thus, the price of a shut-off valve can vary from a few dollars for domestic valves to thousands for industrial valves.

For domestic uses, for the house, residential, and non-specialized tertiary sectors, you can find shut-off valves starting at $4 (watering, distribution of clean water, etc.).

Count between $10 and $50 for more specific shut-off valves (chlorine pool, butane gas).

Finally, you should expect to pay between $200 and $500 for larger diameter valves capable of stopping black water (e.g., for toilets, which circulate water with a high content of materials).

Maintenance and Repair of Shut-off Valves

If the type of shut-off valve has been well studied (material, shut-off, and regulation mechanism), the maintenance of the valve is limited to cleaning from time to time, depending on

– the quality of the fluid flowing through it;

– the particle size of the fluid.

The purpose of cleaning is to prevent the closing mechanism from becoming clogged and prevent the valve from sealing in the closed position (the main function of the shut-off valve).

However, depending on the valve and the medium, some systems may require re-surfacing or replacement of the valve or the shut-off diaphragm.

Excluding the replacement of internal parts of the shut-off valve, the installation and removal of a domestic shut-off valve costs between $50 and $100, depending on the accessibility of the valve, the complexity of the system, and the isolation capabilities.