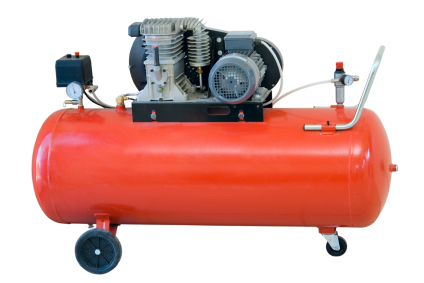

According to the Wikipedia definition, an air compressor is a device that converts power using an electric motor, diesel or gasoline engine into potential energy that is stored in pressurised air. These are mostly found at construction sites and can be used as a power source for electric tools. No matter which air compressor you need, all of them have one common function that is to convert a power source into stored energy in the form of compressed air. It is important to know that there are different types of air compressors and each comes with their uniqueness and drawbacks. We will focus on four types in this blog so as to have a clear view.

1. Rotary Screw Compressor – This is a common type of displacement compressor that is the easiest to take care. These are equipped with an internal cooling system and does not require much maintenance. Typically large and industrial-sized machines, it can be either lubricated with oil or run oil-free. Rotary screw air compressor generates energy via two internal rotors that turn in opposite directions. Rotary screw air compressors are easy to maintain and operate. The air compressors are designed for continuous use and because of the cooling system, its power can be ranged from 5 horsepower up to 350 horsepower.

2. Reciprocating Compressor – The positive displacement machines are used to increase the pressure of the air by reducing its volume. This means that they are taking in successive volumes of air which is confined within a closed space and elevating this air to a higher pressure. These types of air compressors work through a piston inside a cylinder, which compresses the air in order to build pressure and also it displaces it. Reciprocating compressors come in single or multi-stage variations that affect the pressure ranged they can achieve. If you need more power, then the best option to choose is the multi-stage compressor.

3. Axial Compressor – This is a gas compressor that can continuously pressurise gases. Axial compressors are not used in construction projects as they are mostly utilised in high-speed engines on ships or planes. Even though these have a high-efficiency rate, they are more expensive than other types of air compressors as they can go up to many thousands of horsepower. One of the most important reasons why it is reserved for aerospace research.

4. Centrifugal Compressor – These are air compressors that slow and cool the incoming air through a diffuser so that it can build up potential energy. The centrifugal compressor produces a high amount of energy in a relatively small machine. These require less maintenance than the rotary screw or reciprocating compressors.

If you are looking for reliable and durable air compressors, then get in touch with Promptair & Electrical Pty Ltd. They are based in Croydon South, Victoria.